Diamond Cutting

Learn about different types of Diamond cutting.

Diamond Cutting’s four basic steps

Planning

Planning

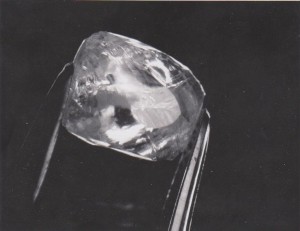

Planning is a crucial step in diamond manufacturing because during this stage the size and relative value of the cut stones that the rough will produce are determined. A person called a planner decides where to mark the diamond rough for fashioning into the most profitable polished gem(s). The planner must consider the size, clarity and crystal direction when deciding where to mark the diamond rough. Incorrectly marking a diamond by a fraction of a millimeter can make a difference of thousands of dollars in some cases. In addition, if one attempts to cleave a diamond in the wrong position, the diamond could shatter and become worthless.

Cleaving or sawing

Cleaving or sawing

Once the planner decides where the diamond should be cut, the diamond is either manually cleaved or sawed. Sawing can be done with a diamond-coated rotary saw or a laser.

Bruiting

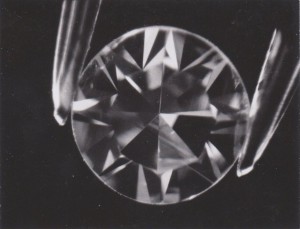

Bruiting forms the basic face-up outline of a round diamond to prepare it for faceting. During the bruiting phase the diamond being bruited is spun on a rotating lathe while another diamond is forced against it, gradually forming the rounded outline. Essentially, one diamond is used to shape the other.

Polishing

Polishing

Polishing is the final stage of the cutting process, giving the diamond its finished proportions. The first and perhaps most crucial polishing stage is blocking. This step lays the foundation for the potential of the diamond’s performance because it establishes the diamond’s basic symmetry. During the blocking stage, the first 17 or 18 facets are made, creating a single cut. For some very small diamonds, the process stops here. Larger diamonds go on to the brillianteering stage. In this process a specialist called a brillianteer, polishes the final facets. It is this stage that will determine how much brilliance and fire a diamond displays. Minor inconsistencies in symmetry and proportions can make the difference between a gorgeous diamond and a dull, lifeless stone.